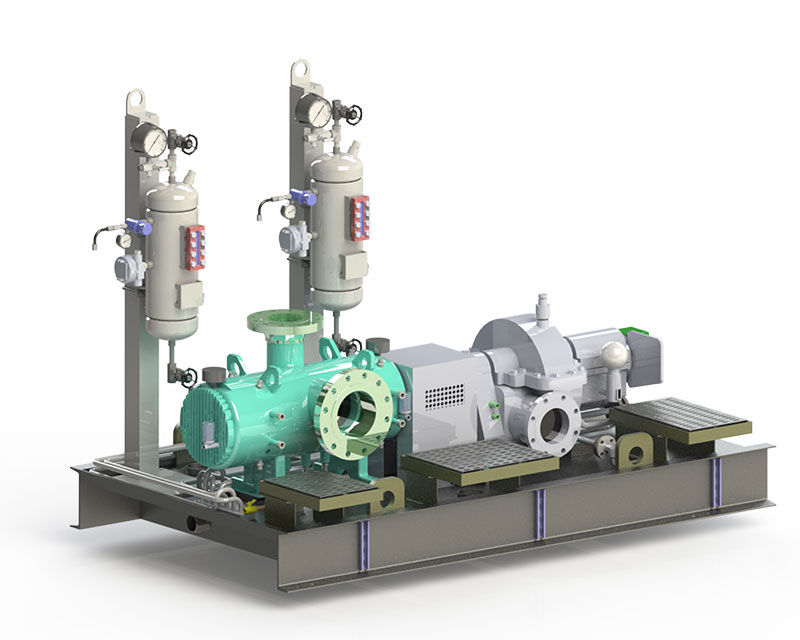

Skid mounted process equipment efficiently distributes and stores equipment for process and modular systems such as gas and fluid systems.

Once the correct process equipment to suit the application is determined, it is mounted to a frame or onto rails or a metal pallet. The skid mounted equipment can then be used as a unit and be transported safely and easily.

A skid mounted process system is a construction block within a larger process system. Though smaller, it remains a vital processing segment. Because of its mobility and geometrical efficiency, skid-mounted process equipment fits perfectly into the tight and deliberate use of space at modern industrial plants. It also lets you bypass the challenges of onsite fabrication of systems including support and utility components.

Skid-mounted systems include electrical wiring and control systems as well. Single connection points for mechanical and electrical use points greatly reduce onsite piping and electrical tasks.

McKenna Engineering excels in the mechanical design and off-site fabrication of skid mounted processing systems and equipment. Our systems are fully optimized, engineered-to-order packages that plug right into the process flow at your plant. They are mechanically, electronically, and control ready for efficient use.

Skid-mounted modular systems allow the equipment to be tested before being shipped. They also provide a safer method of plant modification by minimizing exposure to conditions that contractors are not trained handle. In addition, if required, facility modifications can be completed before skids arrive to your site.

Our proficiency helps ensure that fabrication tasks do not lead to costly plant interruptions.

We design and manufacture an array of these modular systems for the process industry.

Call or message us today to learn how partnering with EWS can make your project a reliable success.