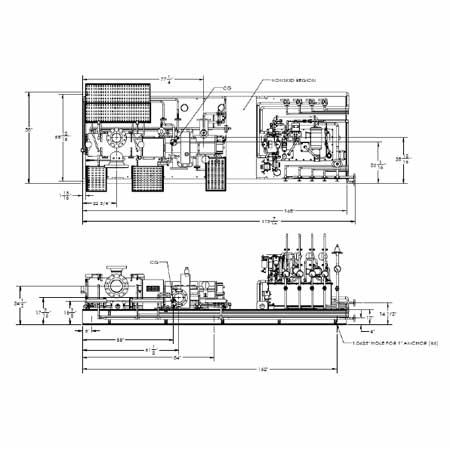

Flare knock-out pumps for Chevron. These pumps are specifically designed for multiphase (gas and liquid) pumping which is required because of the varying vapor pressures on the fluid mixture accumulating in the flare knockout. The flare knock-out is a common collection point for various waste streams coming from the refinery; they are stored in the knock-out until it is time to flare them at which point these pumps turn on to pump the fluid through the flare to burn it as waste.

The unique challenge to this project was that the pumps needed to be able to run in a power outage due to the critical nature of the flare operation.

McKenna Engineering designed / built a steam turbine driver so that in the event of a power outage, this critical segment of the process would remain operational. Additional considerations were the Plan 54 Seal flush system and water cooling on the turbine and pump bearing housings. Each cooling point had its own flow meter and control valve to individually control cooling to each bearing. The Plan 54 seal flush pump was electric driven but had an air motor as a back-up in the event of a power outage.

Call or message us today to learn how partnering with EWS can make your project a reliable success.