Inergy in Kern County, California required a more efficient way to safely offload and transport n-butane from a railroad terminal to a refinery via railroad car. McKenna Engineering worked with the customer to determine the best packaged solution and subsequently designed, built, and delivered a custom, end-to-end solution to meet their needs.

Butane cannot be safely pumped in liquid form due to its high vapor pressure and Net Positive Suction Head required (NPSHr). To safely transfer butane from one tank to another, it must be transformed from a liquid state to a gas. In this application, Inergy needed an evaporation system along with reliable compressors that safely transferred butane between tanks and then to a refinery.

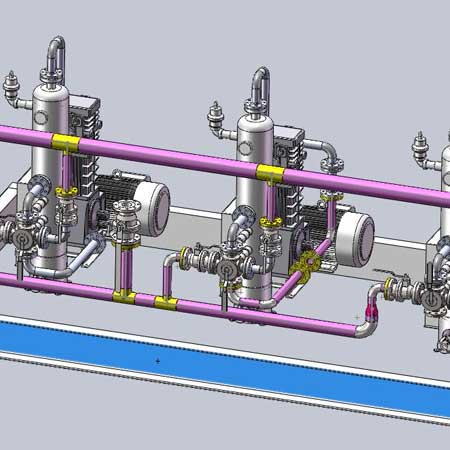

McKenna Engineering provided a comprehensive, end-to-end package that included the design, drawings, fabrication, testing, shipping and start up for a butane transfer application.

McKenna Engineering created a piping and instrumentation diagram (P&ID) along with a Solid Works model that described the process

A compressor package was designed to carefully force the liquid n-butane from one tank to the other with blanket pressure to prevent contamination. The system works by pulling the gas off the top of destination tank, forcing it to the original tank with a transfer pump, and pushing the fluid to the tank compressor.

McKenna Engineering built a controlled evaporation system within a large tank to heat the butane, boil it, and turn the liquid to vapor, so it could be more easily distributed. Once evaporated, the vapor is filtered, impurities and liquid mist are removed, to create pure vapor.

Call or message us today to learn how partnering with EWS can make your project a reliable success.