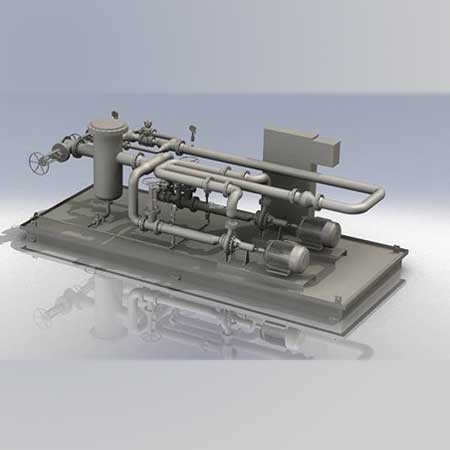

McKenna Engineering & Equipment Co., Inc provided a large west coast oil company with a pipe pigging solution that could provide services for both ultrasonic pipe inspection and cleaning of large oil pipelines. The PIG (pipe inspection gauge) had to be compact enough to move throughout the Los Angeles Basin without interrupting operations and be able to handle a wide range of applications for multiple oil piping systems. This application required a complete trailer mounted smart pig (or intelligent pig) with all the necessary instrumentation, data gathering units and communication systems for remote operators. The entire system had to be designed to accurately control the flow rate between 130 & 2000 gallons per minute @ 450 total dynamic head and, depending on the pipe diameter and line size, travel through the pipeline at a rate of 1ft/sec.

Due to the high volatility and temperature of the crude oil, our team of engineers developed a solution that would meet the customer’s specifications and adhere to all environmental regulations. The entire portable pigging skid package was designed, engineered and fabricated in our Carson, California facility and was built in accordance with API (American Petroleum Institute) specifications. The pig contained dual pressurized seals to ensure crude oil would not be exposed to the environment and the instrumentation controls were integrated with flow, pressure, and temperature gauges/transmitters for metering and detecting anomalies in the pipelines.

Delivered on time, on budget; our team provided installation and startup services to conduct complete and detailed training of the entire pigging packaged system to operators to ensure maximum efficiency and safety of the system.

Call or message us today to learn how partnering with EWS can make your project a reliable success.