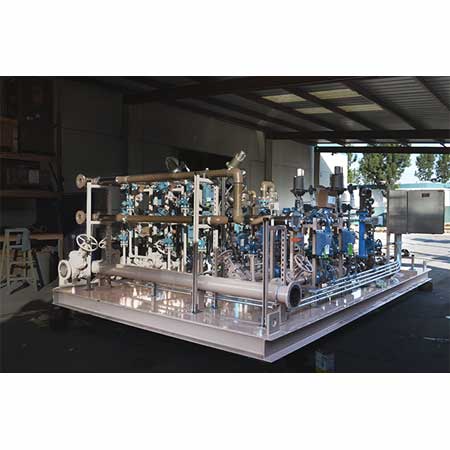

OXY’s Vintage Production in Lost Hills, CA needed two skid-mounted brine and dilution systems for steam generation. The brine skid mixed soft water and saturated brine to produce diluted brine. The diluted brine was sent to two separate banks of primary polishers and then neutralized for steam generation. The acid dilution skid preformed a weak acid cation exchange. The dilution skid mixed soft water, Hydrochloric acid (HCl), and Sodium hydroxide (NaOH), and delivered the diluted solution to one bank of polishers which was then neutralized for steam generation.

Due to the extremes of the water pH levels and higher concentration of the HCl and NaOH, standard carbon and stainless-steel metallic piping systems were not sutiable for the specific corrosive nature of this application. Fiber Reinforced Plastic (FRP) piping was used due to its inert properties and chemical resistance.

McKenna Engineering provided complete engineering, purchase of materials, fabrication, manufacture, testing, and delivery of the equipment associated with the given specifications which would ensure proper containment of the corrosive fluid as well as the blending with neutralizers where needed for additional processing and/or safe disposal.

Call or message us today to learn how partnering with EWS can make your project a reliable success.